about us

We are one of the leading company in Shapar-Veraval GIDC, Gujarat, India in providing various type of services in investment casting, forging and machining since 2009.

We are supported with a high-tech infrastructural facility that assists us to meet the large, urgent and customized requirements of our clients. This facility comprises several units like manufacturing, quality testing, research & development, warehousing & packaging, etc. Well-equipped with the advanced technologies, machines and equipment, these units are supervised under the direction of our talented professionals. Owing to the support of our advanced infrastructure, we have been able to meet clients’ specific demands in timely and well-organized manner.

Our prime objective is to offer the best quality products and services to our valuable clients as per their specific requirements. For this, our experienced team of quality inspectors keeps it sharp eyes on the entire business process. The raw material we use in fabrication process is procured from the certified vendors of the market. In order to ensure premium quality products and services, our quality personnel conduct different stringent monitoring processes during the executing process. We have a distinct quality-testing unit that is equipped with advanced testing techniques and equipment, which help us offer flawless range to the clients.

Our Services

We help our client from concept drawing to finished drawing. Company engineers are ready to assist customers at all stages during order. They can provide suggestions and guidance regarding tolerances and design details, alloy selection and even approximate pricing. Our aim is to help customers select the best manufacturing process for their products. There are wide range of markets that we serve which includes Oil-Petro Chemical, Marine, Machined tools industries, Valves Fitting And Strainers, Fire Fighting Equipments, Automobile and General Engineering.

We request customers to provide following detail so that we can guide you in best possible way with accurate feasibility and cost estimation of the product.

1. 2D Drawing

2. Material Specification

3. Heat treatment condition / Mechanical Properties

4. Annual Quantity Requirement

5. Part Weight

6. 3D Model

7. Application / Industry Sector

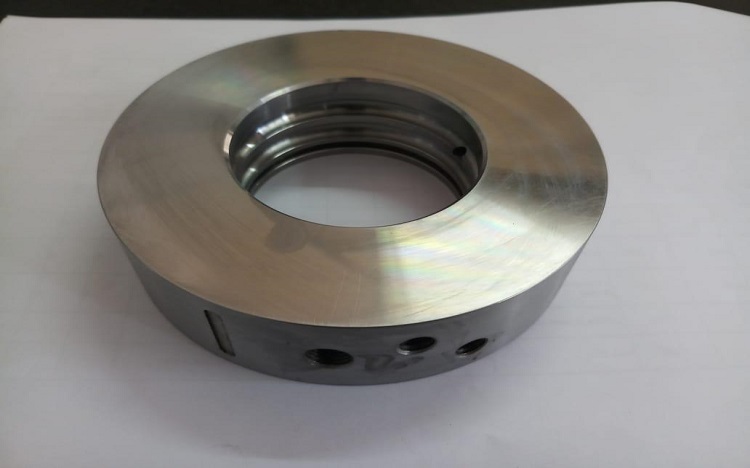

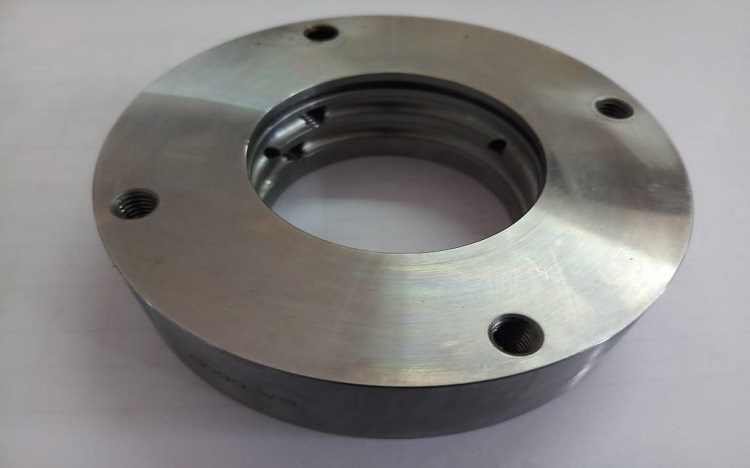

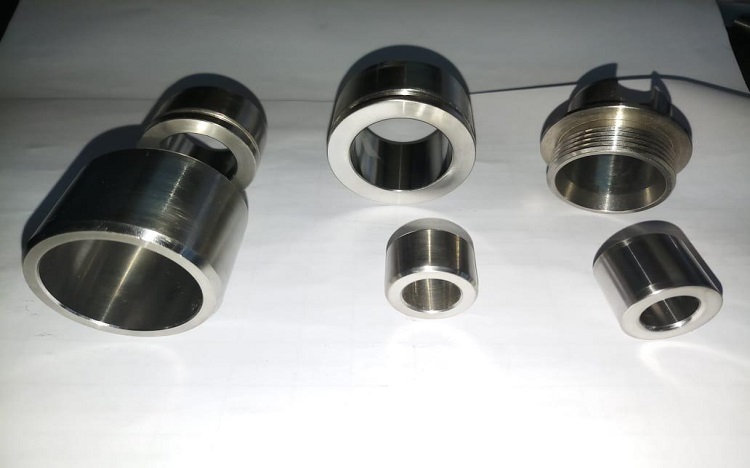

Products

We have established an ultra-modern infrastructure unit that is spread across a wide area. Empowered with cutting-edge technology and ultra-modern machinery, this unit helps us in manufacturing the offered products in streamlined manner. This infrastructure is segregated into various departments like manufacturing, quality testing, research and development, warehousing and packaging unit, etc. These units work in close coordination to meet bulk and urgent orders of clients in an efficient and economical manner. Further, we are supported by a team of skilled professionals, who work round the clock to complete the wide needs of the clients. We have selected our professionals after thorough analysis of their skills in the respective domains. Our professionals are segregated into various departments to make sure smooth operations and high production rate. Apart from this, we conduct different training sessions and industrial workshops to sharpen the skills and enhance the knowledge of our professionals.

Being a quality oriented firm, we ensure to provide utmost satisfaction to the clients by offering them high quality products. In order to maintain optimum quality throughout our business process, we are supported by a team of quality controllers. Our quality controllers strictly scrutinize the entire production process and check all the products on several quality parameters. Considering the storage demands of products, we have built a spacious warehouse that is sustained under the supervision of our experienced warehousing experts. Our warehousing experts help us store these products in safe and well-organized manner. Owing to our ethical business policies, client centric approach and competitive price structure, we have garnered a huge client base all across the country.

We Offer one of the most modern and the most accurate method for manufacturing Metal components in India. We handle both ferrous and non ferrous material and supply casting in carbon steel with Carbon Steels, Low and High Alloy Steels, Stainless Steels, Tool Steels, Precipitation Hardening Steels, Copper and Alloys, Aluminium and Alloys, Nickel Alloys, Cobalt Alloys, Chromium Alloys etc conforming to various International Standards.

Our Technical Capabilities

• Cast product From few grams to 50 Kgs

• Size Parameters : 0.600m x 0.600m x 0.600m

• Mechanical, Chemical, NDT, Hardness, Hydro testing in house and , General Inspection, Micro Structure Test.

• Excellent surface finish and high degree of dimension accuracy

• Castings can be supplied as per customer requirement and try to meet 100% requirements.

• Other than above, in general we can cast any material compositions as per customer’s specifications meeting international standards.

contact us

We are a well-renowned firm, engaged in offering the finest quality products and services as per the specific requirements of clients. Some of the distinguishing factors that make us the first choice in the market are as follows:

1. State-of-the-art infrastructure

2. Experienced workforce

3. International quality standards

4. Timely delivery

5. Ethical business policies

6. Transparent dealings

7. Complete client satisfaction

Visit Us

AARASI INDUSTRIESBehind Kaneria Oil Mill,

Shapar Main Road,

Shapar (Veraval) - 360024

Tal.- Kotda Sangani

Dist.- Rajkot, Gujarat, India